This section will focus on the type of systems used for road and off-highway type vehicles however the techniques will often be similar to other industrial applications. If you are looking for specific information you may need to jump between pages as it's difficult to split the information into manageable blocks.

SYSTEM TYPES

Automotive Braking Systems can be divided into three sections:

(Some Off-Highway machines may not have all of these, for example some will combine Secondary and Parking).

SERVICE BRAKING

The service brakes (footbrake) is normally used to reduce the vehicle’s speed in a controllable manner and to bring it to a halt. It is also expected to hold it stationary on an incline whilst the operator is applying the brake.

It provides a precisely-controlled, low hysteresis, variable braking response to all braked wheels.

SECONDARY BRAKING

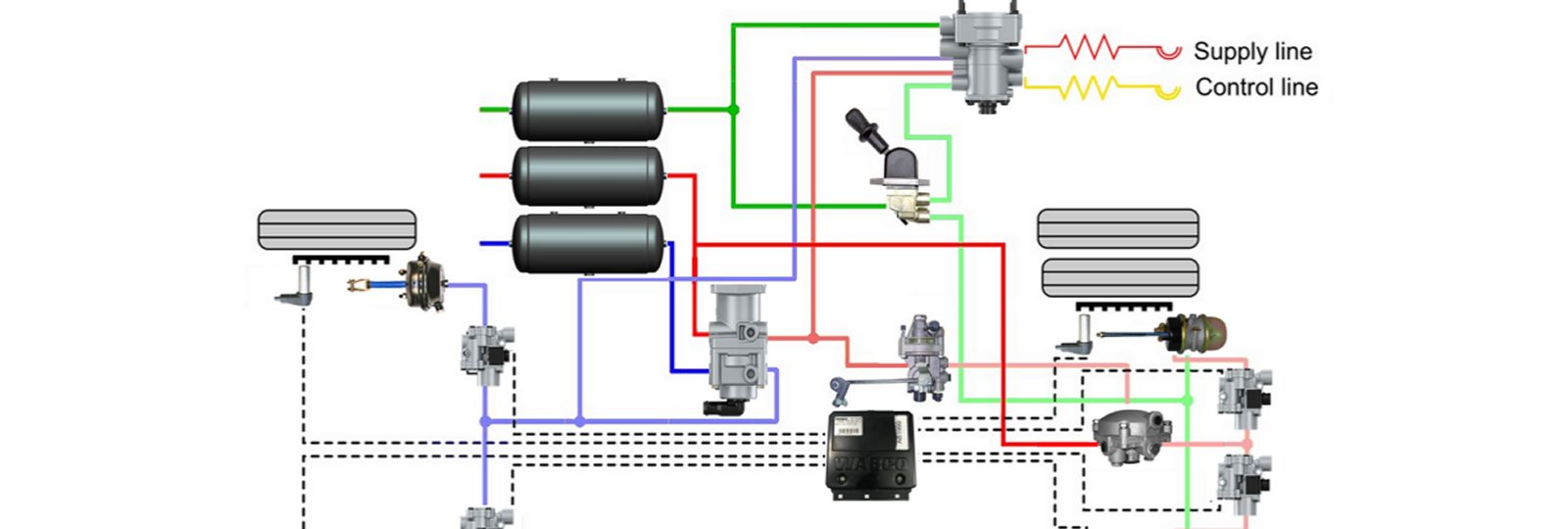

If the service brakes fail, the secondary-brake system must be capable of assuming its functions, although with a reduced performance level.

The secondary brake system need not consist of a separate third system with its own control mechanism; it usually comprises of the intact circuit in a dual-circuit service brake layout or of a parking brake capable of graduated response.

The way a dual-circuit system is split depends on the weight distribution, wheelbase and CofG height of the vehicle but will be designed to give optimum performance whichever service brake circuit has failed.

Figure 1: Typical Service / Secondary Circuit Layouts

Figure 1: Typical Service / Secondary Circuit Layouts

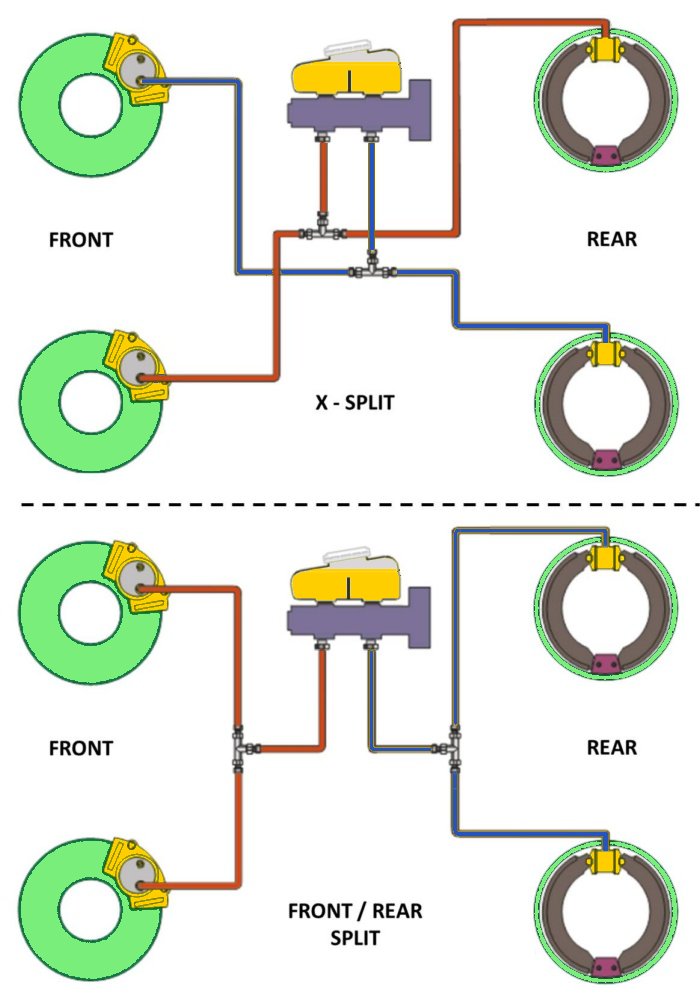

PARKING BRAKING

The parking-brake (handbrake) system assumes the third braking function. it must be capable of maintaining the vehicle in a stationary state, even on gradients and in the absence of the driver. Safety considerations dictate that the parking-brake system must not rely on a stored energy system that may deplete over time to maintain braking, air reservoirs, hydraulic accumulators, batteries etc.

For passenger cars, (ECE Reg 13H), the parking brake actuation must be accessible from the drivers seat and must be capable of being applied when the vehicle is in motion, though it may operate the service brakes under this condition.

Due to the lower torque requirements of a parking brake system they usually operate on a single axle.

Figure 2: Typical Parking Brake System Layouts

OPERATING PRINCIPLES

Depending upon whether a brake system is operated completely, partially or not at all by muscular energy, a distinction is drawn between:

MUSCULAR ENERGY BRAKE SYSTEMS

This type of system is installed in light passenger cars, two-wheeled vehicles and small construction machines. The muscular force applied at the pedal or hand lever is transmitted to the brakes via a mechanical (linkage rods or Bowden cable) or hydraulic (master cylinder, wheel cylinders) relay system.

POWER ASSISTED BRAKE SYSTEMS

The power-assisted brake system is found in passenger cars and light commercial vehicles. This type of unit employs a brake booster (servo unit / master power) to supplement muscular force with energy generated by vacuum or hydraulic pressure. A hydraulic circuit then transmits this enhanced muscular force to the wheel cylinders.

POWER BRAKE SYSTEMS

Power brake systems can be split into two types:

HYDRAULIC POWER BRAKE SYSTEMS

Hydraulic power brake systems are mainly employed in light commercial vehicles, but this type of system is also used for hybrid cars to allow better blending between the foundation brakes and regenerative braking. With this system, the force used to operate the service brakes is entirely non-muscular. These systems employ hydraulic energy (based on hydrostatic pressure) and hydraulic transmission devices.

The hydraulic fluid is stored in energy reservoirs (hydraulic accumulators) containing a compressed gas (usually nitrogen). A flexible diaphragm or bladder, or, alternatively, a piston with a rubber seal (piston accumulator) is employed to separate the fluid from the gas. The hydrostatic pressure, which remains in a constant state of balance with the gas pressure, is generated by a hydraulic pump. A pressure regulator switches the hydraulic pump back to idle whenever maximum pressure is reached.

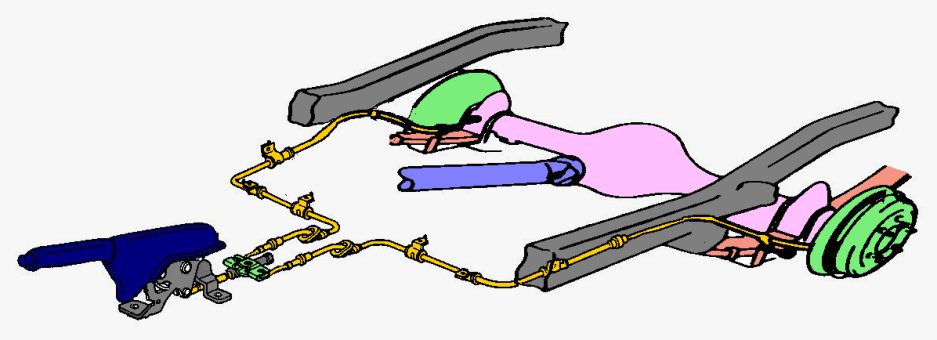

AIR BRAKE SYSTEMS

Air brake systems are mainly employed in heavy commercial vehicles. As with hydraulic power brake systems, the force used to operate the service brakes is entirely non-muscular. These systems employ stored air to operate mechanical brakes using air chambers to convert the air to mechanical energy.

The air is stored in two or more reservoirs which are charged via a number of valves by an engine driven compressor.