|

||||

| home > motorcycles > | ||||

TRIUMPH

I have owned a 1979 Triumph Bonneville T140E since 1984. It's had numerous issues in it's lifetime but it's still nicer to ride than the Honda.

One problem that could have proved very expensive was the damage to the crank caused by the alternator rotor coming loose.

The rotor made by Lucas was an aluminium casting into which were cast the magnets and a steel driving sleeve. The issue was that the fixing of the sleeve into the casting was not robust, probably due to shrinkage in the casting. This caused a vibration to be set up between the casting containing the magnets and the steel sleeve keyed to the crank. Due to lack of experience I didn't spot this until it had completely ripped the key and keyway to bits.

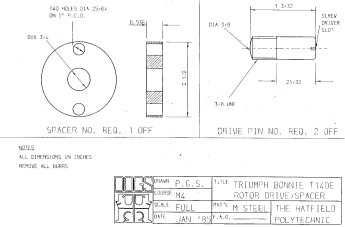

The obvious solution of a new rotor and crank didn't sit to well with my student grant so an adaptor was made to drive the rotor directly from the primary chain sprocket.

The sprocket already has two tapped holes for extraction so fitting two drive pins into this was easy. I had to drill two small holes into the rotor, avoiding the magnets and make a spacer to support the whole thing. It's never been disturbed since 1985 so I guess it was successful.

Picture of Rotor Drawing

of Adaptor

Drawing

of Adaptor

As you can imagine the Bonnie was getting ready for a rebuild. The clutch was worn out, the wiring was dodgy, the front mudguard was broken, etc etc.... Time to spend some money.

After stripping it down the first job was to weld on some permanent brackets for the oil cooler and filter onto the frame and correct the alignment of the centre stand stops to try and prevent it breaking another stand. After that it was time for a coat of paint on the frame. I'm fortunate enough to live within a couple of miles of Cambrian Powder Paints who specialise in motorcycle parts.

During the sand blasting, disaster struck when holes appeared in the lower frame tube on the prop stand side. There wasn't any sign on the outside so I wasn't expecting it on this frame.

After taking advise I decided to cut away the lower half of the frame tube. If I had cut through it would need jigging to guarantee alignment. I bought a short length of tube from EBay and spent hours making it fit the cutout.

After it was TIG welded in place, dressed and painted the repair could not be seen. I sprayed an anti rust penetrant into the frame to prevent it happening again.

I'm shocked to find the quality of Triumph parts has really gone down the drain. I've had to return, modify or tweek 95% of all new components I've bought. Did I buy them from the wrong place? I don't think so....

I bought a new stainless steel master cylinder from the Stafford Show a couple of months ago and it's gone rusty at the first sign of rain!!!

I'm told there are two different manufacturers of SS master cylinders. Look at the picture and judge for yourself...

Tri-Cor admitted they made their first batch from the wrong grade of Stainless Steel and replaced this one free of charge. The new one looks OK.

I'd had a look at a couple of filler caps at the Stafford Show and wasn't impressed with the chrome finish on the knurled side. I saw some 'value caps' on Ebay being sold by Heritage Motorcycles. The feedback was good, as was the price.

BUT after a weeks use I went to fill the tank up and coulded get it back on because the seal had swollen. Of course I'd already left good feedback so my complaints fell on deaf ears.

more to follow.

home • inspiration • motorcycles • brakes • caravans • robotwars • flying • cars • projects • links • sitemap

E-mail: web@thewombles.net

© Splash_Womble